Description

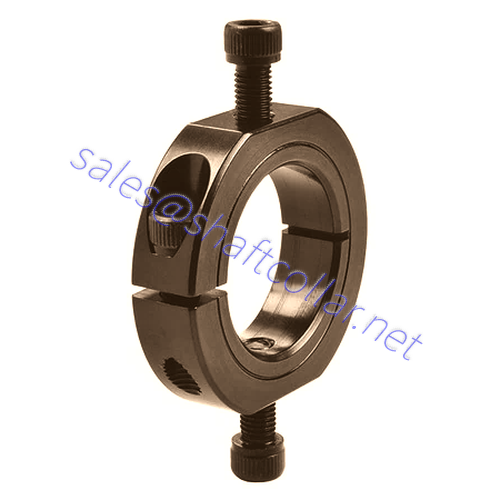

Mountable shaft collars are used to mount sensors, fixtures, and other assemblies to shaft collars or each other. They are available in three different styles: outer diameter holes, outer diameter flats and holes, and quick release. The holes in all styles are tapped and fit standard caps, Torx, or set screws for flexibility based on what needs to be mounted. They are available in 1215 lead-free steel with a black oxide finish, high-strength 2024 aluminum, and 303 stainless steel in bore sizes ranging from 3/8” to 2” and 10mm to 40mm. This variety of styles and materials allows designers to match shaft collar performance to application requirements.

Mountable shaft collars are designed with flats and holes in the outer diameter for easy mounting of shaft collars to each other or adjacent assemblies. • Ruland clamp style does not mar the shaft, is easy to remove, and is indefinitely adjustable. • Mountable shaft collars are used for guiding, spacing, stopping, mounting, and component alignment. • Bore 0.5000 in, OD 1 1/8 in, Width 0.406 in, Black Oxide Steel, Screw #8-32, Wrench 9/64 in, Seating Torque 49 lb-in.

Dimension of Mountable Shaft Collars

- Bore Dia.: 1/2″

- Material: Black Oxide 1215 Lead-Free Steel

- Number of Pieces: 1

- Collar Style: Clamp

- Outside Dia.: 1 1/8″

- Dimension Type: Inch

- Width: 0.406″

- Screw Size: #8-32

- Operating Temp. Range: -40 Degrees to 350 Degrees F

- Clearance Dia.: 1.281″

- Screw Material: Alloy Steel

- Item: Shaft Collar, Mountable,1/2″, Steel

- Country of Origin (subject to change): United States

How Does the Shaft Collar Work?

A collar is a small mechanical fastener that goes around a shaft or rod and serves various functions. They are used, for example, as spacer elements on flagpoles and for securing sprockets and gears to shafts. They can also be used as stops in drive trains. They are used in various applications and are very useful.

There are many different types of collars, each with its own advantages. For example, clip-on collars work really well with fairly constant pressure. They are available in one-piece shaft collars and two-piece shaft collars versions. However, the two-piece shaft collar version offers greater holding power and resistance to shock loads.

Types of Shaft Collars

Clip-on collars work well when used under a constant load. It also makes fine-tuning easier. The clamping screw is embedded in the ring. This allows the collar to be threaded onto the shaft without moving. However, it may be difficult to remove the collar for replacement.

Another design is the trapezoidal thread collar. This type of ring can withstand higher thrust loads than conventional smooth annular rings. This style has interlocking studs on both sides to reduce vibration. These are ideal for clean room environments.

There are also heavy-duty collars for superior shock resistance. They are designed for steel mill equipment and off-road vehicles. They have large cross-sections and robust clamping screws.

The collar can be made of metal or plastic. The material affects its performance and overall durability. Plastic collars, for example, are less expensive but offer less support. The material can also be treated to increase corrosion resistance.