Shaft Collar Manufacturers

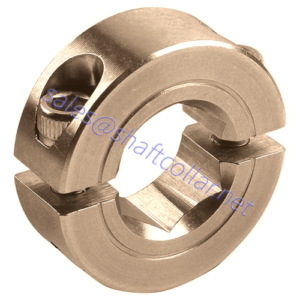

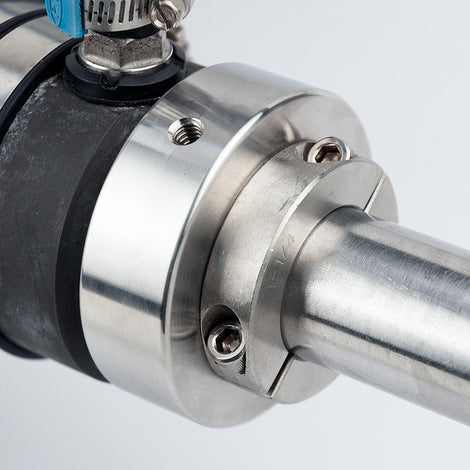

Shaft collars are machine components featuring a simple design that consists of a round metal or plastic ring with a clamp screw and/or screws. Tightening the screws causes the ring to tighten or loosen around the shaft. When securely tightened, shaft collars with flange can serve as mechanical stops or hold components in place along a shaft.

轴的套环

What is a Shaft Collar Used For?

Shaft collars can be used in almost any factory or manufacturing facility. While it’s a small piece overall, it’s most often used as a mechanical stop that holds pulleys, bearings, and sprockets in place. It is used every day in factories and facilities around the world. Shaft collars are most often used as mechanical stops, but can also be used to space and locate components or bearing surfaces. Setscrew Shaft Collars, One-Piece Shaft Collars, 两件轴项圈 These common components are vital to manufacturers and facilities around the world and are used every day. While there aren’t many major innovations in shaft collars, sometimes small tweaks and improvements can make a difference.

Shaft Collar for Sales

If you need customized products, or the products you need are not found in our website, or need a product catalog, don’t worry, more of our products are still being uploaded. You can email us directly, we will reply you within 24 hours!

How Are Shaft Collars Made?

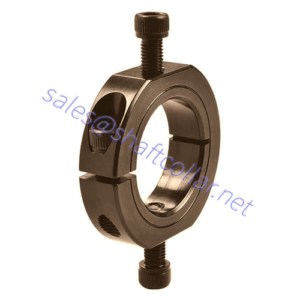

The type of collar used depends on the application. Two-piece collars provide more support than one-piece collars. The two-piece design also offers installation advantages. The two-piece collar can be repositioned along the shaft without removing other components. They also provide better resistance to shock loads.

Two-piece collars are a great option for workers. They are easy to remove and install, and can be removed without any damage to the shaft. This type of collar has greater holding force than a one-piece collar and can be used at full installation torque.

Selecting the proper collar for an application requires understanding the limitations of the system. For example, if the application is designed to operate in a clean room environment, then a collar made of titanium is ideal. The material is lightweight, has a low outgassing rate, and can withstand extreme temperatures.

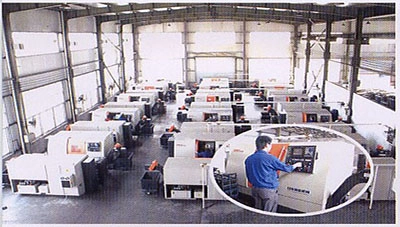

公司的视频

How Do You Install a Shaft Collar?

While it is important to understand how effective a shaft collar with a set screw will be in an application, many assemblies benefit from or require a specific style. Some shaft collars with flange will require infrequent adjustment or disassembly after the initial installation. In this case, a one-piece shaft collar clamp type or set screw shaft collar clamp may be suitable, as either can be installed quickly and easily. The collar must be frequently disassembled in other assemblies, and other difficult-to-remove components are installed on the shaft. In this case, a two-piece style is beneficial as it can be installed and removed without disturbing other components.

Quick shaft clamping collars with a cam clamping lever are ideal for applications requiring frequent axial adjustment along the shaft. By skipping the manual torquing of the screw, adjustments with this collar style are several times faster and more convenient.

Benefits of Shaft Collars

当用于在电力传输、运动控制、自动化和其他原始设备制造商和维修应用程序、轴领提供几种好处,包括:

- 安装方便. 轴项圈的设计便于安装和拆除。 他们中的许多人可以被安装在不消除其他轴组件和/或使用的情况下结束轴是无法访问。

- 广泛的多样性. 可在一个范围广泛的设计和材料(例如,耐腐蚀和重型材料)、轴项圈可以制造以承受各种环境和工作条件,包括暴露于化学品、油和高温。

- 高定制. 轴领的具有广泛的尺寸,样式和材料可供选择,使他们可以量身定做以满足几乎所有的应用。

How Do I Remove a Shaft Collar?

Shaft collars, usually made of steel, are ring-shaped metal or plastic devices that clip onto the shaft and hold other components in place. They are used in many different applications. There are many types and styles of collars to choose from, and choosing the right collar is an important part of application design.

The type of collar used for the application depends on the type of shaft and the clamping force required. For example, the retention of a collar depends on its outer diameter and the materials used in its construction. If the outer diameter of the collar is larger than the bore of the shaft, the holding force will be reduced. Larger collar outer diameters require more torque to bend around the shaft.

在接触!

鹏欣感到自豪的是我们的声誉作为一种创新的供应商广泛的市场。 我们已经赢得了这个信誉,把我们的客户第一次。 我们努力提供持续的产品和服务支持我们的客户需要保持最高的生产率。 我们很高兴回答你的任何问题可能有,或者提供的服务和知识产品的专业知识的需要。