Shaft Collar Manufacturers

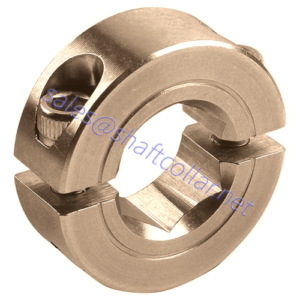

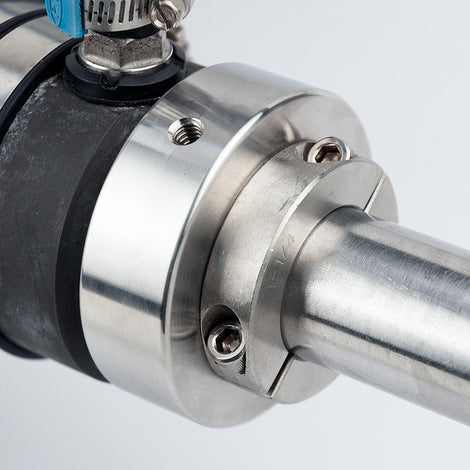

Shaft collars are machine components featuring a simple design that consists of a round metal or plastic ring with a clamp screw and/or screws. Tightening the screws causes the ring to tighten or loosen around the shaft. When securely tightened, shaft collars with flange can serve as mechanical stops or hold components in place along a shaft.

Shaft Collar

What is a Shaft Collar Used For?

Shaft collars can be used in almost any factory or manufacturing facility. While it’s a small piece overall, it’s most often used as a mechanical stop that holds pulleys, bearings, and sprockets in place. It is used every day in factories and facilities around the world. Shaft collars are most often used as mechanical stops, but can also be used to space and locate components or bearing surfaces. Setscrew Shaft Collars, One-Piece Shaft Collars, Two-Piece Shaft Collars These common components are vital to manufacturers and facilities around the world and are used every day. While there aren’t many major innovations in shaft collars, sometimes small tweaks and improvements can make a difference.

Shaft Collar for Sales

If you need customized products, or the products you need are not found in our website, or need a product catalog, don’t worry, more of our products are still being uploaded. You can email us directly, we will reply you within 24 hours!

How Are Shaft Collars Made?

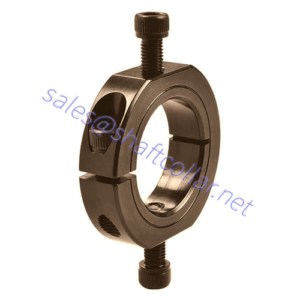

The type of collar used depends on the application. Two-piece collars provide more support than one-piece collars. The two-piece design also offers installation advantages. The two-piece collar can be repositioned along the shaft without removing other components. They also provide better resistance to shock loads.

Two-piece collars are a great option for workers. They are easy to remove and install, and can be removed without any damage to the shaft. This type of collar has greater holding force than a one-piece collar and can be used at full installation torque.

Selecting the proper collar for an application requires understanding the limitations of the system. For example, if the application is designed to operate in a clean room environment, then a collar made of titanium is ideal. The material is lightweight, has a low outgassing rate, and can withstand extreme temperatures.

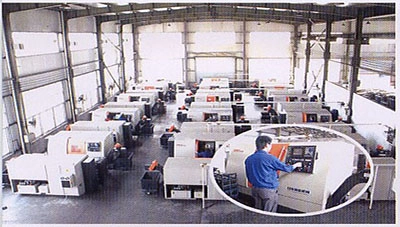

Company Video

How Do You Install a Shaft Collar?

While it is important to understand how effective a shaft collar with a set screw will be in an application, many assemblies benefit from or require a specific style. Some shaft collars with flange will require infrequent adjustment or disassembly after the initial installation. In this case, a one-piece shaft collar clamp type or set screw shaft collar clamp may be suitable, as either can be installed quickly and easily. The collar must be frequently disassembled in other assemblies, and other difficult-to-remove components are installed on the shaft. In this case, a two-piece style is beneficial as it can be installed and removed without disturbing other components.

Quick shaft clamping collars with a cam clamping lever are ideal for applications requiring frequent axial adjustment along the shaft. By skipping the manual torquing of the screw, adjustments with this collar style are several times faster and more convenient.

Benefits of Shaft Collars

When used in power transmission, motion control, automation, and other OEM and MRO applications, shaft collars offer several benefits, including:

- Easy installation. Shaft collars are designed for easy installation and removal. Many of them can be installed without removing other shaft component and/or used in situations where the end of the shaft is inaccessible.

- Broad versatility. Available in a wide range of designs and materials (e.g., corrosion-resistant and heavy-duty materials), shaft collars can be manufactured to withstand a variety of environmental and operating conditions, including exposure to chemicals, oils, and high temperatures.

- High customizability. Shaft collars have a wide range of sizes, styles, and material options available, allowing them to be tailored to suit virtually any application.

How Do I Remove a Shaft Collar?

Shaft collars, usually made of steel, are ring-shaped metal or plastic devices that clip onto the shaft and hold other components in place. They are used in many different applications. There are many types and styles of collars to choose from, and choosing the right collar is an important part of application design.

The type of collar used for the application depends on the type of shaft and the clamping force required. For example, the retention of a collar depends on its outer diameter and the materials used in its construction. If the outer diameter of the collar is larger than the bore of the shaft, the holding force will be reduced. Larger collar outer diameters require more torque to bend around the shaft.

Get in touch!

Pengxin is proud of our reputation as an innovative supplier to the broad markets we serve. We have earned this reputation by putting our customers first. We strive to provide the ongoing product and service support our customers need to maintain peak productivity. We are happy to answer any questions you may have, or provide you with the service knowledge and product expertise you need.